Lean 5s

wednesday 8 videa

5S rendszer - Lean módszerek, eszközök, technikák - LeanToolBox. Az 5S egy lean módszertan, amely a „rend és tisztaság" tartalomnál lényegesen több jelentéssel bír. Megértése és helyes alkalmazása a lean bevezetésének és sikeres fenntartásának alapfeltétele. Az 5S módszer egy szabványosítási rendszer, mely segít a biztonságos, tiszta és hatékony munkahely létrehozásában és .. 5S - What are The Five Ss of Lean? | ASQ. Learn what 5S is, how it helps create a clean, organized, and productive workplace, and see a case study and resources for implementing it. 5S stands for sort, set in order, shine, standardize, and sustain, and is a methodology for visual control and lean production.. 5S - Wikipédia. Az 5S egy leaneszköz, -módszer, amelyet elsősorban a vállalati munkahelyek rendezett kialakításának érdekében alkalmaznak

omorashi org

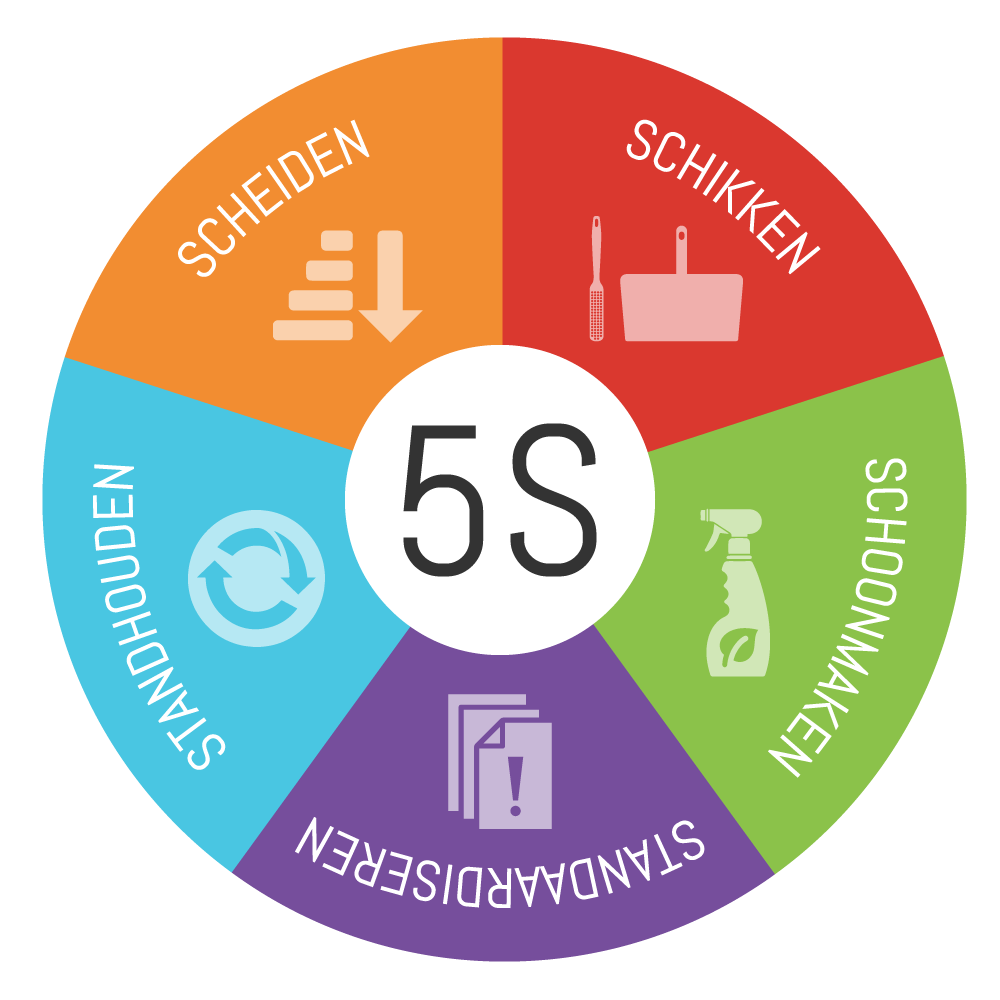

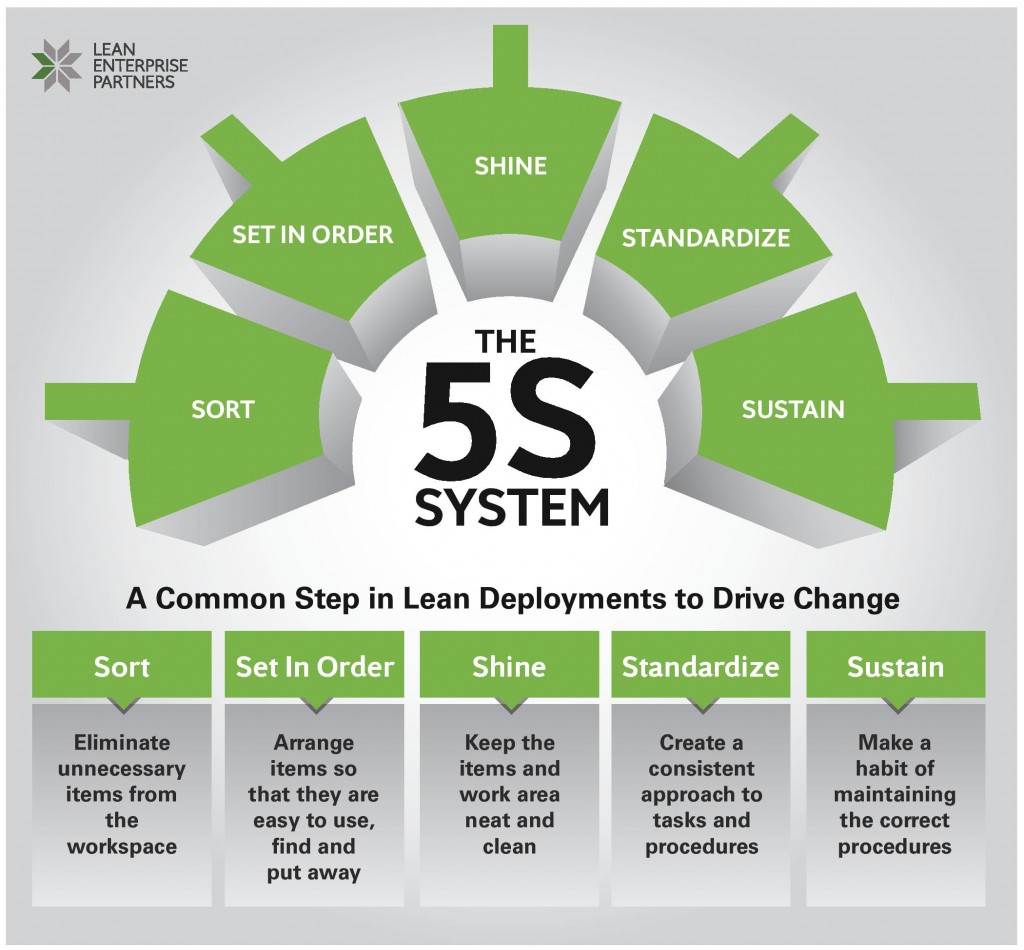

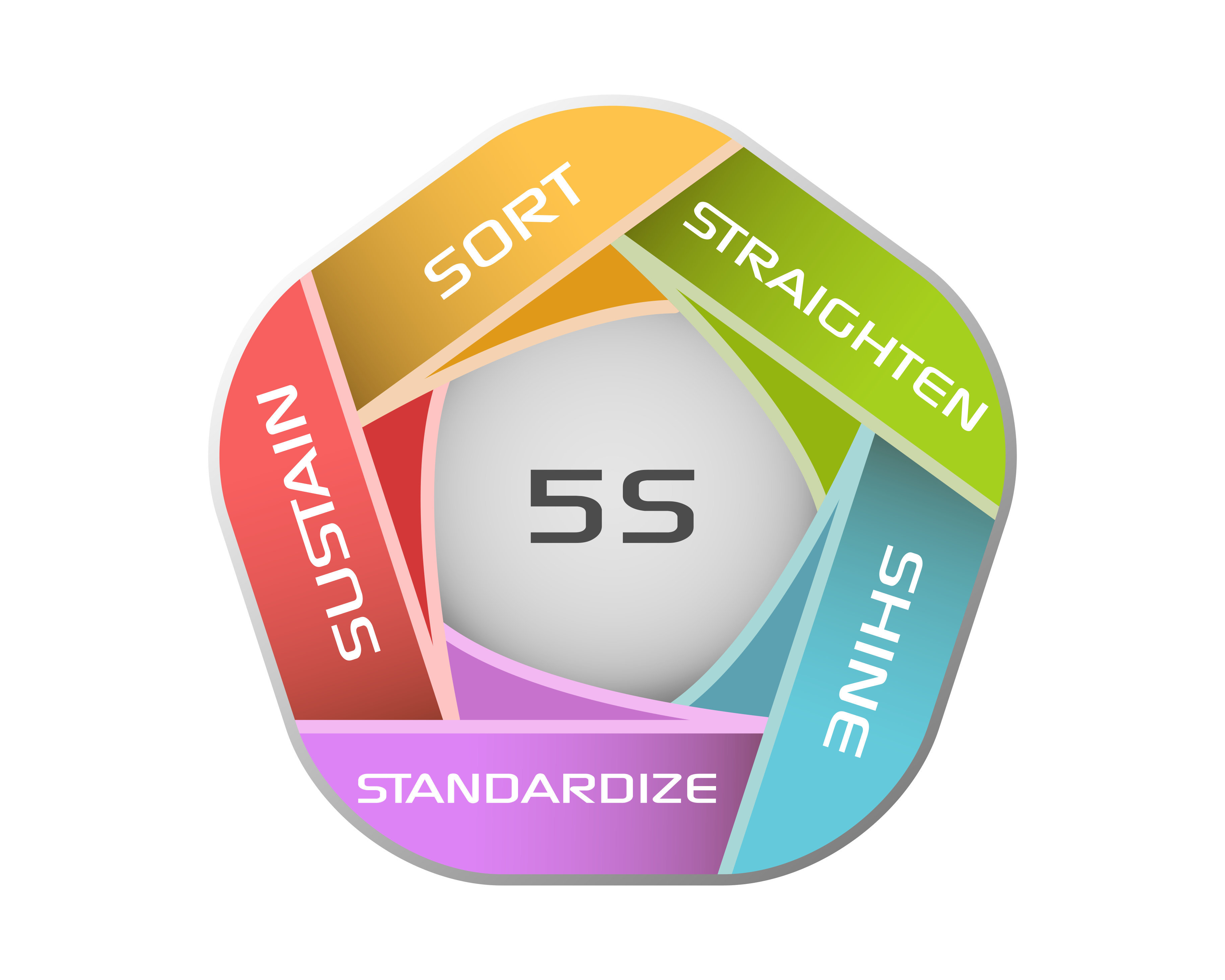

. Sokfelé tévesen „rend és tisztaság" tartalommal használják, miközben a módszer ennél lényegesen több. Megértése és helyes alkalmazása a lean bevezetésének és sikeres fenntartásának .. What Is the 5S Methodology? | Lean Production. 5S is a five-step methodology that, when followed, creates a more organized and productive workspace. In English, the 5Ss are: Sort, Straighten, Shine, Standardize, and Sustain. 5S serves as a foundation for deploying more advanced lean production tools and processes.. 5S - Kaizen Pro | Lean tanácsadás, folyamatfejlesztés, tréning, diagnózis. Útmutató a lean gyakorlati alkalmazásához A lean legfontosabb eszközeinek leírása egy helyen: online, pdf és könyv formában 5S Szerző: Kosztolányi János Alapszint Mi az 5S? A módszer öt S betűvel kezdődő japán kifejezésről kapta a nevét: Seiri - Szelektálás Seiton - Elrendezés Seiso - Takarítás Seiketsu - Standardizálás Shitsuke - Fenntartás. 5S (methodology) - Wikipedia. 5S methodology. 5S resource corner at Scanfil Poland factory in Sieradz. 5S is a workplace organization method that uses a list of five Japanese words: seiri (整理), seiton (整頓), seisō (清掃), seiketsu (清潔), and shitsuke (躾). These have been translated as sort, set in order, shine, standardize, and sustain. [1]

marha hátszín ár

. Miért olyan sikeres az 5S, miben rejlik az 5S titka. Az 5S lényege .. Az 5S az egyik legfiatalabb, mégis felméréseink alapján a legelterjedtebb termelékenység fejlesztési (Lean) módszer. Az 5S-t 1991-ben mutatta be OSADA

parkside száraz nedves porszívó

. Miért olyan sikeres az 5S, miben rejlik az 5S titka Az 5S lényege, hogy az alapját teremti meg a többi Kaizen tevékenységnek.. 5S - What is it? | Lean Enterprise Institute. 5S is a methodology to create a visual workplace that supports lean production and continuous improvement. Learn the meaning, purpose, and implementation of 5S, and how to avoid bureaucratic pitfalls.. 5S tábla - 5S rendszer - lean - LeanToolBox - kellék a sikerhez!. Az 5S tábla alkalmazása. A tábla elkészítése fontos feladat egy 5S-projekt bevezetése során. A kezdeti oktatások és tapasztalatszerzés után a táblán tudjuk elhelyezni a szükséges információkat: előtte-utána képek; audit eredmények; auditlapok, információk; előrehaladás mértéke; célok/cégpolitika; munkatársak .. Guide: 5S - Learn Lean Sigma. Within Lean 5S is one of the key tools sued for organizing the workplace and is widely used in manufacturing and other industries to improve efficiency, safety, and productivity by following the 5 steps of 5S which are Sort, Set in order, Shine, Standardize, and Sustain.. Lean menedzsment technikák: 5S módszer - SolverGroup. Az 5S alkalmazása nagy lendületet ad a munka hatékonyságának növeléséhez mind a termelő-, mind az irodai területeken, azáltal, hogy. csökkenti a munkaráfordítást, gördülékenyebbé teszi a munkát. Emellett az 5S növeli a vevők és ügyfelek bizalmát, és ezáltal is hozzájárul az eredményesség növeléséhez.. 5S módszer és alkalmazása - Kvalikon. 5S módszer és alkalmazása. 5S módszer és alkalmazása. Az 5S az egyik legfiatalabb, mégis felméréseink alapján a legelterjedtebb termelékenység fejlesztési (Lean) módszer. Az 5S-t 1991-ben mutatta be OSADA. Miért olyan sikeres az 5S, miben rejlik az 5S titka. Az 5S lényege, hogy az alapját teremti meg a többi Kaizen .. 5S Lean & 5S Principles in the Workplace | SafetyCulture. 5S is a systematic way of organizing workplaces by eliminating waste, improving flow, and reducing the number of processes where possible. It applies the five principles: Sort (seiri), Set in order (seiton), Shine (seiso), Standardize (seiketsu), and Sustain (shitsuke).. What is Lean 5S Methodology | Training & Overview - Lean Smarts. Learn what 5S is, how it originated, and why it is a key practice for lean organizations. 5S stands for sort, set in order, shine, standardize, and sustain, and helps achieve workplace efficiency and abnormality detection.. Fenntartható 5S módszer képzés - Lean Six Sigma. Az 5S módszer egy öt lépésből álló folyamatot jelent, mely nevét azokról a tevékenységekről kapta, amelyeket azért végzünk, hogy a biztonságos, hiba és veszteségmentes folyamatokat megteremtsük. Az eredeti japán szavakat igyekeztem az adott tevékenységet legjobban leíró „S"-sel kezdődő magyar szóra fordítani. Kell egy 5S bevezetési terv!. Lean Roundup: 5S - Lean Enterprise Institute. Practicing 5S is a way to: create standards that reveal problems, support the basic stability needed to sustain incremental gains, reduce waste in all forms, build a disciplined workplace where teams focus on value -creating work, and nurture the essential sense of shared purpose needed to continuous improve to take root.. The 5S Methodology | GoSkills. The visual workplace that 5S methodology is meant to enable has roots going back centuries. However, the current form is usually considered to have been part of the evolution of the Toyota Production System (TPS) following the second world war

vízhatlan tok strandra

. 5S is usually undertaken as part of a larger initiative, such as a Lean or Lean Six Sigma project.. A leanről - Mi a lean? Mi a célja? Hogyan segíthet neked?- LEI. A „lean" fogalmat a Toyota vállalat működésének leírására alkotta meg a Jim Womack (PhD) által vezetett kutatócsoport, az MITs International Motor Vehicle Program (MIT Nemzetközi Gépjármű Program) keretén belül, a késői 80-as években.. LEAN 5S, what is it? - Sixsigma DSI. LEAN 5S refers to five Japanese terms that describe the steps in the 5S system for visual management. The Japanese terms are Seiri (Seiri), Seiton, Seiso, Seiketsu and Shitsuke. The five SS in the English translation are Sort, Set in Order, Shine, Standardize, and Sustain.. 5s, ergonómia haladótréning - Lean logisztika

orrmandula műtét után orrfújás

mapei plastimul fiber plus

. 5S-metoden utvecklades hos Toyota i Japan; var och en av de fem grundpelarna har ett .. Introduction to 5S Methodology Training - Lean Manufacturing . - YouTube. Learn what 5S methodology is all about in this fun introduction video, which is perfect for teaching lean manufacturing principles. 5S is a housekeeping prac.. What is Lean 5S? | BRADY - BradyID.com. What is Lean / 5S? The Benefits and How to Get Started. Originated in Japan, 5S is a lean manufacturing methodology used to help eliminate waste, optimize productivity and increase efficiency. Companies who implement 5S enjoy a cleaner, safer and more organized workplace. 5S is one of the most widely adopted techniques.. Hvad er 5s lean? Hvordan bruger man 5s lean? - BlivProjektleder. 5s lean, også kendt som 5s modellen, er et effektivt redskab til at skabe en arbejdsplads, der er ren og ordentlig. 5s lean består af de fem ser: sorter, sæt i system, systematisk rengøring, standardiser og selvdisciplin

dr domokos emőke rendelési idő

hatoslottó nyerőszámok 5 hét

. 5S Lean is a systematic approach to workplace organization and standardization based on five Japanese words that start with the letter S. Its a part of lean manufacturing and can be applied to any work environment, including offices, labs, and production floors. The goal of 5S is to create a clean, organized, and efficient workspace.. PDF 5S /VisualWorkplace Handbook - gotopac.com. lean improvements remain clearly visible, readily understood, and consistently adhered to long after the kaizen event is over. Visual Workplace and 5S go hand in hand. One of the main purposes of 5S is to prepare the work environment to hold visual information. From that perspective, 5S is a method, while creating a visual workplace is the goal.. 5s | What is a 5S Event? | Kaizen Event | Lean manufacturing - SixSigma.us. What is a 5S Event? November 27th, 2018. 5S is a popular and commonly-used tool in Lean manufacturing and is used for the optimization of workplace conditions. Often, 5S is used as a key building block within many lean continuous improvement efforts. This is because this tool not only offers a solid base on which improvements can be established .. The Five Principles of Lean - Project Management Institute. The five principles of lean. The five principles of lean are: Specify value from the standpoint of the end customer. Identify all the steps in the value stream, eliminating whenever possible those steps that do not create value. Make the value-creating steps occur in tight sequence so the product will flow smoothly toward the customer.. Lean Tools | Lean Manufacturing Tools | Lean Meaning - Tech Quality Pedia. Lean tools | 5S 5S is a basic foundation stone of Lean manufacturing, TQM, and TPM methodologies. 5S is the first towards continuous improvement and an organization cannot succeed without lean 5S. The 5S methodology is a systematic and continual improvement technique to eliminate the waste or non-value-added activities that originates from a poorly organized workplace.. What is 5S Methodology: 5s Implementation Plan - Simplilearn. 5S is a methodology for creating an organized and productive workspace by sorting, straightening, shining, standardizing, and sustaining. Using 5S as a foundation, advanced processes and tools to implement lean production can be developed. 5S is the perfect tool to identify the first improvement projects in your company to eliminate waste.. The Principles of 5S in Lean Manufacturing | 5S Systems | Rever. The Principles of 5S. The 5S methodology is one of the main methods for improving manufacturing processes & practices. It enables companies to streamline manufacturing processes and organize a workforce more effectively, ensuring that the entire staff of a manufacturing plant is involved with productivity, efficiency, and safety goals.. What is 5S; Seiri, Seiton, Seiso, Seiketsu, Shitsuke. The Concept of 5S. 5S is a methodical way to organize your workplace and your working practices as well as being an overall philosophy and way of working. It is split into 5 phases, each named after a different Japanese term beginning with the letter "S"; (Seiri, Seiton, Seiso, Seiketsu, Shitsuke) hence the name 5 S.. Introduction to 5S: A Journey towards Workplace Excellence. Variants include 6S. The 5S methodology is an improvement tool for organizing and maintaining a disciplined and productive workplace. It facilitates the creation of a better working environment by reducing waste while improving efficiency, safety and quality. 5S represents five fundamental practices that starts with the letter S.. The 5S Shine Pillar - Inspection and Maintenance - 5S Today. The 5S Shine Pillar - Inspection and Maintenance. January 15, 2019 by Jesse Allred. The third step of 5S is Seiso, a Japanese term translated to mean Shine. During Shine, workers are encouraged to do a deep cleaning of their space, ensuring there is no grime, dust, or oil spills remaining. However, it is important to remember that cleaning is .. Learn What 5S is and How it Applies to Any Industry - YouTube. httpa://GembaAcademy.com | In this video Ron Pereira, of GembaAcademy.com, explains exactly what 5S is and why its not optional for those looking to impleme.. 5S | 5S Methodology | What is 5S | Quality-One. The 5S Method is a standardized process that when properly implemented creates and maintains an organized, safe, clean and efficient workplace

okos kukta

. Improved visual controls are implemented as part of 5S to make any process non-conformances obvious and easily detectable. 5S is often one element of a larger Lean initiative and promotes continuous .. What is the 5s System? | Definitions, Core Concepts & Principles .. A 5S map is a diagram or floor plan that provides an overview of a work area, process, or station

koponyeg szabadszallas

. What is 5S? - Planet Lean. 5S IN LEAN. The importance of 5S in a lean transformation cant be stressed enough. In fact, in this compelling article, Michael Ballé went as far as listing the lack of 5S efforts as one of the cardinal sins hindering our ability to kaizen at the gemba.In this piece, Michael writes: "The point of 5S is people learning, through the regular practice of the five Ss, to create the kind of .. 5S - Wikipedia. 5S on Japanissa kehitetty työpaikkojen organisointiin ja työmenetelmien standardointiin keskittyvä menetelmä, jonka tavoitteena on kasvattaa työn tuottavuutta. Tähän pyritään välttämällä kaikenlaista hukkaamista ja tuhlaamista, poistamalla ei-arvoa tuottavaa toimintaa, sekä parantamalla laatua ja turvallisuutta, sekä luomalla visuaalisesti miellyttävä ja tehokas työpaikka.. Lean Manufacturing Tools and Techniques | Lean Production. Learn the 25 most important types of lean tools and techniques to start using today. TOPICS. Intro to Lean. What is Lean Manufacturing? Top 25 Lean Tools The . 5S eliminates waste that results from a poorly organized work area (e.g., wasting time looking for a tool). Learn more about 5S.. 5S Infographics - A Brief & More Detailed Overview. A Brief Overview of 5S A More In-Depth Look at 5S Click here for a fun, online learning activity on 5S. The following is a transcript of the infographic above: 5S is a five-step organization technique to create and maintain an intuitive workspace. Sort - Keep only necessary items in the workplace. Review tools, parts, and […]. What Is 5S? - Kaizenworld. 5S is the foundation of all improvements and is the key component of establishing a Visual Workplace. Both are a part of Kaizen — a system of continual improvement which is a component of lean manufacturing. A 5S program focuses on having visual order, organisation, cleanliness and standardisation. The results you can expect from a 5S program .. How to implement Lean 5S Visual Workplace Organization? | Operational .. Lean 5S Visual Workplace Organization is a workplace organization methodology to improve productivity, by eliminating waste, and Quality, by reducing variation. The 5S Visual Workplace Organization methodology also facilitates a structured dialog about standardization which builds a clear understanding between employees, of how work should be done.. Interesting relation between 5S and Kaizen - SixSigma.us. Lets be more clear now on definitions. • Kaizen - a system of continuous improvement where effective process and flow are part of the system. • Lean manufacturing - a method for eliminating waste in a manufacturing system - also called lean production or lean. • 5S - the part of the Kaizen system that establishes a workplace .. Lean For Dummies Cheat Sheet. Lean leaders lead from gemba, where the action happens. They know the only way to truly understand what is happening is to go to the place where the action occurs. Once there, they apply 3Gen or the 3 Actuals: . and standardize while eliminating any unsafe conditions; this is known as 5S+. Example value-stream map (VSM) When you have created .. Miksi 5S? — Lean Lion. 5S on kuitenkin usein ymmärretty väärin, sillä se ei ole siivousohjelma! Se on jokapäiväinen ja jokaisen omaan työhön kuuluva toimintamalli. Se on yksi Lean johtamismisfilosofian perustyökaluista, jonka toteuttamisen jälkeen voidaan paremmin tunnistaa ja poistaa hukkia (arvoa lisäämättömiä toimintoja) yrityksen prosesseista.. 5s in Lean Six Sigma: Heres What You Need to Know - UMass. The Definition and Breakdown of 5S Lean Six Sigma. The philosophy of 5S presents a method of focusing and thinking to organize better and manage a workspace. The 5S methodology targets the eight wastes defined by the Lean Manufacturing system and is one of Lean manufacturings most popular and fundamental components. Its a simple, common .. 5S Concept Certification - Management and Strategy Institute. 5S Concept Certified (5SC) 5S is a workplace organizational method that uses a list of words to describe how to organize a work space. Those words are Sort, Straighten, Shine, Standardize and Sustain. 5S was originally developed in Japan as part of Just-in-Time manufacturing techniques. Now, 5S is being applied to a wide variety of industries.. Measuring 5S Performance - 5 Essential Tips - Creative Safety Supply. Along with these, learn how 5S affects your specific business and how you can make sure the facility is getting as much out of this methodology as possible. Check out Creative Safety Supply for all your 5S, Lean, and continuous improvement product needs. Similar Posts. 11 Tips and Tools For a Better 5S Workplace; The Difference Between 5S and .

babérmeggy ültetése

. What is 5S in Manufacturing? - Vector Solutions. 5S is a lean manufacturing method that originated in Japan and is widely used in manufacturing and other industries to improve organizational processes, efficiency, and waste reduction in the workplace. The term "5S" stands for five Japanese words, each beginning with the letter "S.". The 5S system is meticulously designed to create a .. Floor Marking is a Necessary Measure in the 5S and Lean Manufacturing .. Floor Marking and 5S. Far more than colorful lines and simple geometric shapes that help mitigate hazards, floor marking is a useful organizational tool that can prove invaluable for anyone designing a straightforward 5S program.In the same way that floor marking can be used to delineate hazards within the workplace, it can also be used as a vivid visual reminder of where tools should be .. What is 5S in Six Sigma? - dummies. For Six Sigma, 5S can be invaluable for reducing waste. High-performing processes and workplaces are always characterized by organization and cleanliness. The whole point is to reduce or keep out waste, and the method that helps you with that is called 5S. The process behind 5S began decades ago in Japan as a means of immediately engaging .. A Practical Approach to the Successful Practice of 5S - iSixSigma. While some Lean Six Sigma (LSS) practitioners consider 5S a tool, it is more than that. 5S, abbreviated from the Japanese words seiri, seito, seiso, seiketsu, shitsuke, is not just a methodology, it is a culture that has to be built in to any organization which aims for spontaneous and continuous improvement of working environment and working conditions.

. Lean Six Sigma: Definition, Principles, and Benefits - Investopedia. Lean Six Sigma is a managerial approach that combines Six Sigma methods and tools and the lean manufacturing/lean enterprise philosophy, striving to eliminate waste of physical resources, time .. Lean 6S; 5S + Safety. What is Lean 6S. Many companies will tell you that they implement lean 6S; 6S being 5S plus the added step of safety. 5S is a methodical method to improve your housekeeping and standardize your processes making them more efficient and less stressful for your employees